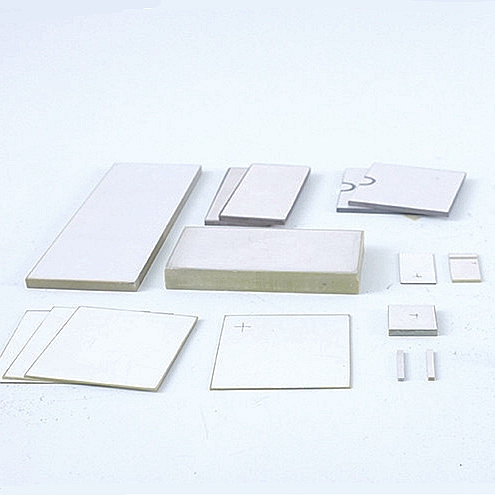

Ultrasonic welding transducer copper electrodes

The ultrasonic welding system is suitable for welding procedures such as all-plastic nose bridge welding, post-folding welding, breathing valve welding, multi-layer seam welding and ear band welding of masks and medical protective clothing. It is also suitable for welding diapers, packaging bags or metal materials. Process. The ultrasonic welding system includes an ultrasonic generator, a transducer, a horn and a welding head. Its general working principle is: the ultrasonic generator converts low-frequency alternating current into high-frequency alternating current, and converts electrical energy into high-frequency vibration through the transducer Mechanical energy, when the welding head acts on the contact surface of the thermoplastic, it generates tens of thousands of high-frequency vibrations per second. The high-frequency vibration transmits ultrasonic energy to the welding area through the upper weldment. The upper weldment and the lower weldment in this area generate friction , Generate local high temperature, after ultrasonic action, the pressure lasts for a few seconds to make it solidify and form a solid molecular chain to realize ultrasonic welding. When the ultrasonic welding system is used for welding masks, diapers, packaging bags or metal materials, it does not require solvents, adhesives or other auxiliary materials. It is safe, environmentally friendly and pollution-free, and replaces traditional manual welding. It can not only improve production efficiency, but also be effective lower the cost.

In the transducer, the ultrasonic welding transducer copper electrodes sheet is used to conduct the positive or negative electrode of the piezoelectric ceramic. In the prior art, the pins on the electrode sheets are flush with the board surface. When the piezoelectric ceramics and electrode sheets are press-fitted on the transducer, the distance between two adjacent electrode sheets is reasonable before the wires are welded. , But after welding the wires on each electrode piece, the solder (such as soldering) flows along the axial direction of the transducer and thus has a certain width, which causes the distance between two adjacent electrode pieces to shrink. When the transducer is working, High-voltage ignition may occur between adjacent positive ultrasonic welding transducer copper electrode sheets and negative ultrasonic welding transducer copper electrode sheets.

Reviews

There are no reviews yet.