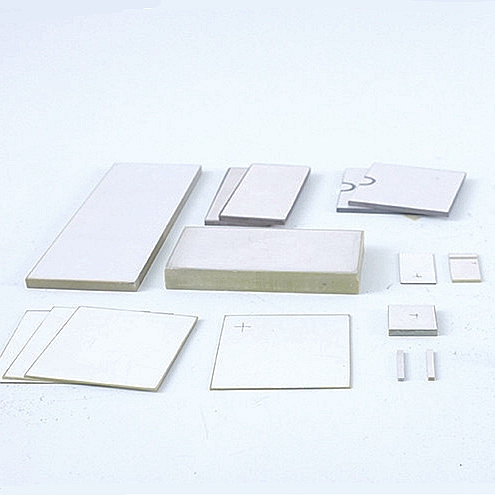

Piezo Ring 25x10x5mm for ultrasonic welding

1. Dimension: Φ25 × Φ10 × 5 mm

2. Material: PZT8 or PZT4

3. Technical parameter:

3.1 Resonant Frequency Fr. 62.0khz ± 2.0khz

3.2 Couping Factor KP 0.52

3.3 Static capacitance pF: 1100±15%nf

3.4 Dielectric Loss tgδ ≤ 0.5%

3.5 Piezoelectric constant d33 ×10 -12 C/N:≥280

3.6 Test in 10 days poling

3.7 density kg/m3:>7650

Piezo Ring 25x10x5mm for ultrasonic welding

With the rapid development of welding technology, there are various welding methods at present, and people’s requirements for welding are also increasing.

The higher the higher, the pursuit fast, non-toxic, firm and convenient welding method, while the traditional welding application is

There are many shortcomings in plastic and metal technology.

Plastic products have entered every corner of life. Correct

The traditional method of plastic welding is mainly to connect the components through thermal fusion. This way of welding

It has high toxicity and low efficiency, and it also produces certain additives to pollute the environment.

Arc welding is one of the metal welding

A common method, but for special applications such as the welding of electronic devices, wire mutual welding is commonly used

Electric welding methods can no longer meet the requirements, and problems such as low efficiency, strong toxicity, and environmental damage have restricted the transmission.

The development of unified welding technology.

Therefore, it is necessary to find a new type of welding process. Ultrasonic welding technology

The main purpose is to convert electrical energy into high-frequency mechanical vibration through a transducer, which drives the high-frequency movement of the welding machine’s abrasive tools.

The workpiece is placed on and in contact with the surface of the abrasive tool, so that high vibration will be generated while welding the surface of the workpiece, making the welding

An instant high temperature is generated locally in the joint area, and a certain pressure is applied at the same time, the ultrasonic is turned off, and the welder waits for a few seconds.

The pieces can be solidified together, thereby playing the role of welding.

Ultrasonic welding has no pollution and speed

The advantages of fast speed, no sparks, high welding strength, and safety began to be widely used in the industry. In my daily life

Ultrasonic welding products can also be seen at any time in life.

Reviews

There are no reviews yet.